DockPort

Your suspended oyster aquaculture solution. Designed with a focus on solving the most challenging issues oyster farmers must overcome.

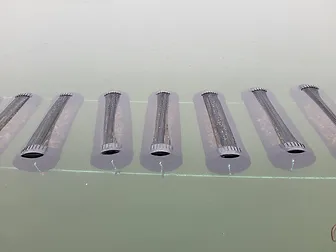

BOBR is deployed on two static lines instead of one. This feature along with its round shape and low profile significantly reduce risk of storm damage or loss. BOBR's low profile reduces exposure to wind while the cylindrical shape provides minimal drag from passing waves. In the unlikely event of gear damage or loss, all of the components can be replaced individually. In 2022 Hurricane Fiona put BOBR to the ultimate test, all lines stayed in place and no units were lost. Let storms tumble your oysters, not steal them!

BOBR units may be defouled manually on small farms simply by rotating the units by hand to expose the fouled portion. On commercial-scale farms, the work platform performs this task. The platform travels along the lines, BOBR units roll up the intake ramp across the work table and into a heated seawater dunk tank for a few seconds then back into the water. This provides more effective elimination of fouling organisms without flipping heavy cages or lost grow days.

BOBR floats are loose within the BOBR growth unit. This permits quick and easy adjustment of cage bouyancy. Typically two floats will be used but farmers may add or remove floats to achieve certain goals. For more wave action/tumble - add a float. To increase stocking density, add a float or two. To sink more easily, remove some floats. To avoid a storm remove all the floats.

BOBR growth units have a volume of 76 liters, more than double that of most other cages. BOBR units are individual and able to respond dynamically to wave action providing natural tumble. This combination of ample space and natural tumble produces oysters with a deep cup and great symmetry.

BOBR floats are contained within the growth unit, this enables a very low visual profile. BOBR tends to blend in rather than stand out. BOBR units are black in color, curved in shape, and float only a few inches above the water's surface. The low profile feature of BOBR growth units may be an important advantage in more populated areas.

The BOBR growth system enables farmers to increase farm productivity while decreasing required physical effort. Reduced shore trips, natural tumble, easy mechanized tumble, far easier sink and refloat, husbandry tasks done on the lease with BOBRs on the lines, and faster, more effective defoul all contribute to increased farm productivity.

The BOBR system was designed with the environment in mind. Lower carbon emission due to reduced shore trips. Smaller shadow than square bag systems. Off-bottom over-wintering capability mitigates potential impacts on the benthic environment. Greater storm security and easier storm avoidance means less gear loss.